Any company that has a data center knows how important it is to mitigate failure risks and maintain an efficient environment that promotes uptime. From layout design to temperature monitoring, there are various factors that can contribute to failures and outages. These disruptions can lead to lost data and lost time; however, if you’re diligent, you can reduce these risks of failure before they occur.

One of those hazards is zinc whiskers. You may not know what they are or that you have an issue before you start having problems in your data center. It’s important to catch zinc whiskers early on and take steps to remove them before your data center gets damaged.

Related: Best Practices for Data Center Cleaning

How Zinc Whiskers Affect Data Centers

Zinc whiskers are tiny filaments that form on the surface of items that are electroplated with zinc and are commonly found in data centers, especially older ones. That plating helps prevent rust but presents a new problem: zinc whiskers.

Zinc whiskers aren’t easily noticeable and can be challenging to diagnose. Because they form underneath the floor tiles and their structural supports, they’re rarely ever in your line of sight, and they’re about the size of a particle of dust.

However, zinc whiskers begin to cause problems when they start breaking off of the coating, which can happen at any time. Even the smallest amount can be troublesome for your data center.

After they detach, the whiskers can enter your data center’s airflow circulation, blowing the zinc into your units and computers through their intakes. Due to the whiskers’ size, case fans and air filters can’t catch them efficiently. When they pass through IT loads, the whiskers can cause problems from intermittent short-circuiting to long outages and eventually equipment failure.

The filaments act similarly to small wires since zinc is a conducting material. They’re also electro-charged because of the electroplating process, which means that the zinc particles are essentially low-capacity fuses. They have a DC fusing current of anywhere from 10 to 30 mA3, meaning that if they cause a short circuit, that current can vaporize the zinc whisker, leaving no evidence behind of what caused the shot.

If left unchecked, a zinc whiskers problem can cause issues all over your data center. Let’s talk about how to remove them.

Signs of Zinc Whiskers

It can be challenging to identify whether or not zinc whiskers are present in your data center, especially if you only experience periodic problems.

The filaments themselves are barely visible, and numerous instances of zinc whiskers might be chalked up to no trouble-found reports. However, even if your center does not experience any signs, your tiles and flooring are worth inspecting.

However, you can more often capture early signs of their existence in how they affect your equipment. The quicker you search for zinc whiskers, the less damage they’ll do.

The first indication is a high failure rate that spans a range of makers and suppliers. It could be an electrical wiring problem or something related to the supplier if specific pieces of equipment continually short-circuit. But if the scarcities and electrical concerns affect resources randomly, it could be zinc whiskers in your airflow.

Second, try to observe the timing of the shortage circumstances. A random pattern may still mean zinc whiskers are a possibility. However, if there are other concerns after you do any flooring or cable upkeep work, construction, rearranging of heavy equipment, or moving flooring tiles for any reason, there’s a high likelihood of it being the fault of zinc whiskers.

Some of the typical problems following zinc whiskers entering your air flow consist of periodic short circuits, voltage variances, and signal disturbances. In addition, when the delicate microcircuits get infected, the existence of zinc whiskers can trigger complete equipment failures and system resets.

These concerns can spell out catastrophe for your data center and lead to downtime, expensive repair work, or data loss. If you see any of these issues, mainly if they occur in groups or not long after shifting devices and flooring tiles, it’s essential to look for the source of the problem. If you come up empty-handed, you can count zinc whiskers as a prospective suspect.

Identifying Zinc Whiskers

You can conduct a visual assessment of the flooring. While the filaments are challenging to see, you can recognize them if you know what to look for and where to look. However, it’s still a difficulty, and the approach does not guarantee that you’ll have the ability to spot their existence.

Once you’ve flipped the tile, look for a dull, consistent color, a gray that appears a little glossy, or a texture that looks like dust. As you move or tilt it, you may capture reflective sparkling or minor twinkling on the surface, which usually shows the existence of these crystals.

Tilt the tile sideways and, using a magnifying glass, look carefully for 1 to 10-millimeter-long filaments standing up like little hairs. You can likewise shine a light or laser tip parallel to the surface area, assisting you to see them better. If you observe any of this, zinc whiskers are likely the source of your electrical issues.

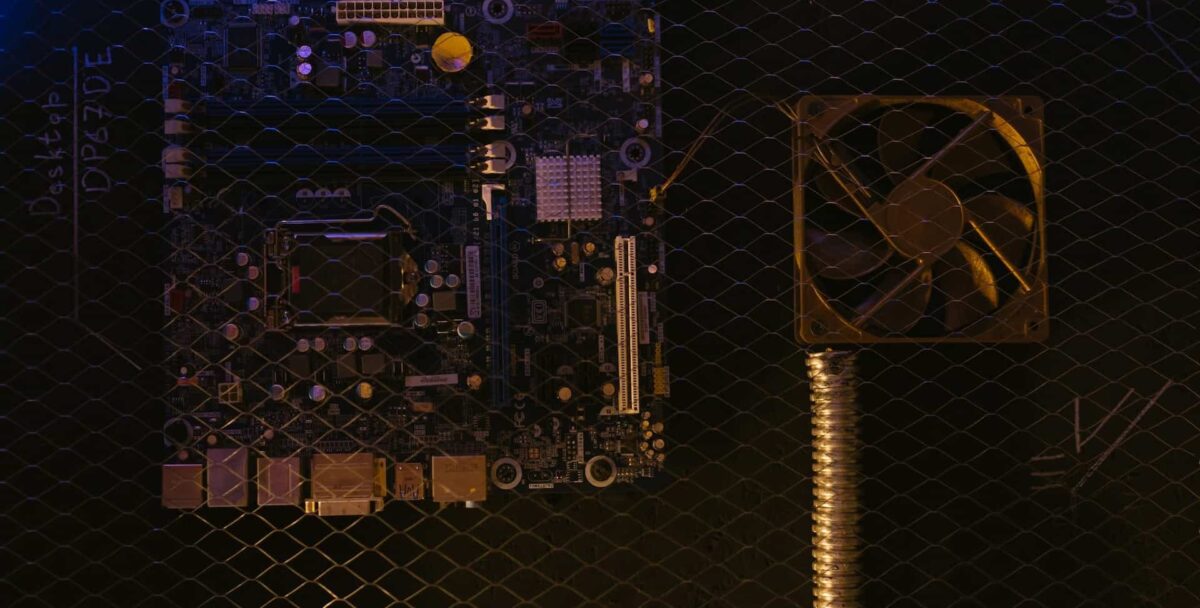

You can look at the affected circuit boards from your equipment. You may be able to see tiny zinc whiskers, but there’s also a chance they vaporized due to the short circuit. If no whiskers are present, it does not rule them out as a prospective cause.

Removing Zinc Whiskers

Once you’ve identified that you have a zinc whiskers problem, they aren’t too challenging to get rid of. It will take some time, and you might have to partner with a specialist, but in most cases, you should be able to continue your data center operations without interruption. It’s a manageable process, but you’ll need to initiate it immediately after finding zinc whiskers—waiting will result in more damage and outages.

There’s only one way to guarantee that you’ll get rid of all of it: removing the source. Simply cleaning or coating floor tiles isn’t enough, and it also poses another problem—introducing whiskers into your airflow. Also, because zinc whiskers are so small, it’s almost impossible to tell if you’ve removed them all or not.

Whether the whiskers are growing underneath your floor tiles or on other zinc-plated surfaces, it’s crucial to replace them with alternatives that aren’t zinc-electroplated. Luckily, because of the prevalence of zinc whiskers in data centers that have older flooring, there are plenty of options available to remove and prevent zinc whisker problems.

The replacement process isn’t necessarily difficult, but it requires care and caution—the whiskers can continue breaking off and entering your data center’s airflow during removal. Before starting, you’ll want to redirect, reduce, and contain the airflow to help prevent broken-off whiskers from harming your sensitive equipment.

Once you’ve created those safeguards, you’ll need to start removing any tiles or elements that have zinc electroplating. Then, you’ll bag each piece individually to minimize the number of particles entering the air and prevent breakage. If you’re working with a specialist, they’ll provide you with plenty of assistance. Workers that are on-site during this process should wear HEPA masks to prevent them from breathing in any of the zinc particles.

Once you’ve removed the zinc-plated elements from your data center, you can use a HEPA vacuum to clean out your air plenum and get rid of any leftover particles in your cooling system. Once the entire area is clean, it’s time to start installing the new flooring. It’s recommended to replace everything at once to help prevent future occurrences of zinc whiskers.

Related: Data Center Cleaning & Dust Control

Installing HEPA filters throughout the center can help catch and absorb the small particles that will likely break off and enter your IT loads and devices.

Preventing Zinc Whiskers

The best way to help protect your data center from zinc whiskers is to take measures to ensure they can’t start growing in the first place. Because they only grow on zinc-plated surfaces, installing new flooring with tiles that don’t have that plating is a surefire way to prevent zinc whiskers. However, you still need to ensure that the flooring has proper corrosion protection since rust is also hazardous for data centers.

Some of the best products have a coating of hot-dip galvanized zinc, which provides a layer of zinc for the surface, but without causing the stress of electroplating that can cause expansion and lead to zinc whiskers. With these coatings, you can get a high level of rust protection without the risk of whiskers forming.

Powder coatings are a more affordable solution, although not quite as effective. Many data center floors are now tiled with steel or aluminum, so corrosion resistance is a must. All in all, as long as you get rid of your old zinc-electroplated metals, your data center shouldn’t have any issues with zinc whiskers.

Even if you do install new non-zinc-plated flooring in your data center, it’s essential to keep up with regular cleanings to ensure that other issues don’t begin to show themselves.

Don’t want to deal with the zinc whiskers by yourself? C&C specializes in the removal of zinc whiskers without compromising any of your systems in the process!

Related: Data Center Cleaning: Tips & Supplies

Last Updated on January 20, 2023 by Josh Mahan